On July 19 and 20, we invite you to a brand new industry event TechDays 2023, dedicated to the latest technologies and their application in industry.

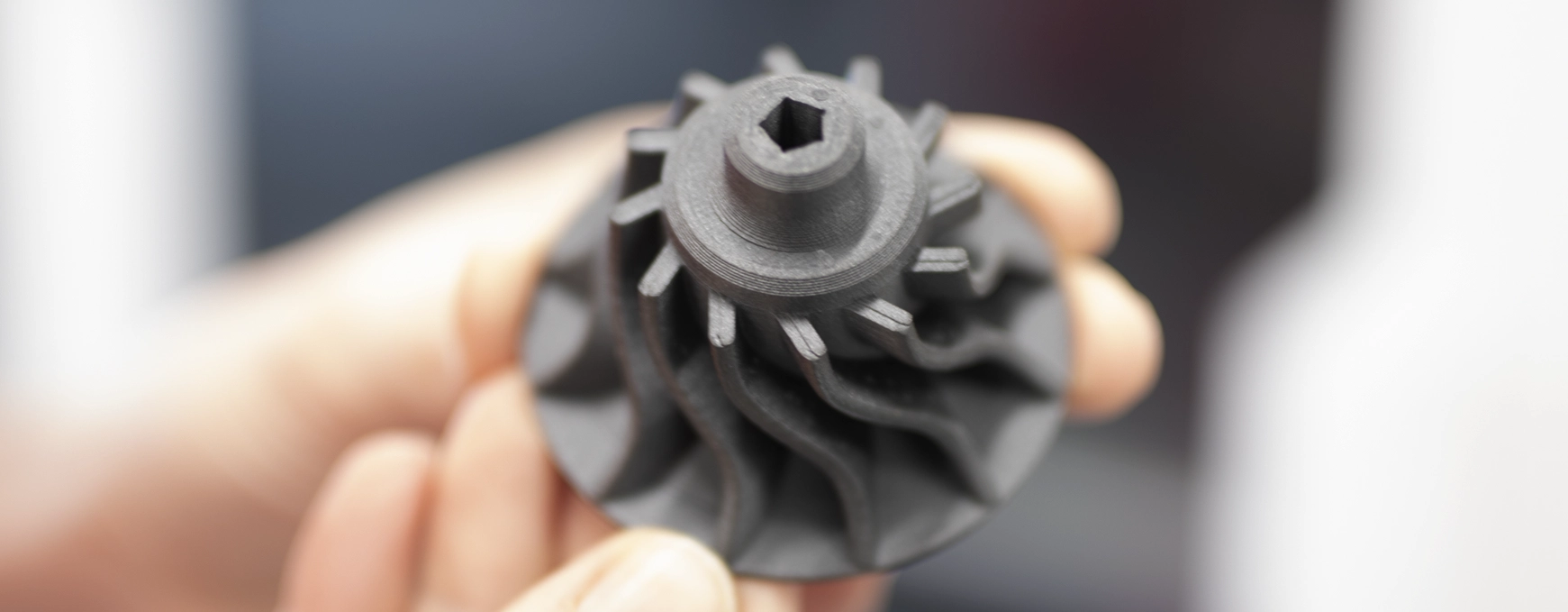

PEEK CF with carbon fibre is one of the best filaments for FDM 3D printing.

Visit VSHAPER Booth on FORMNEXT Exhibition in Frankfurt am Main in days 15 – 18 November 2022. Take part in 5AX application competition and listen the presentation in your own language. We will be presenting our Ecosystem in 3 languages: German, French and English.

Innovative VSHAPER solutions guarantee efficient control of settings of printing conditions and investigation of printed filament dynamics. The ability of precise 3d printing of individual elements of different sizes and complexity, forming a functional mechanism, was a key factor for the INVEST company.

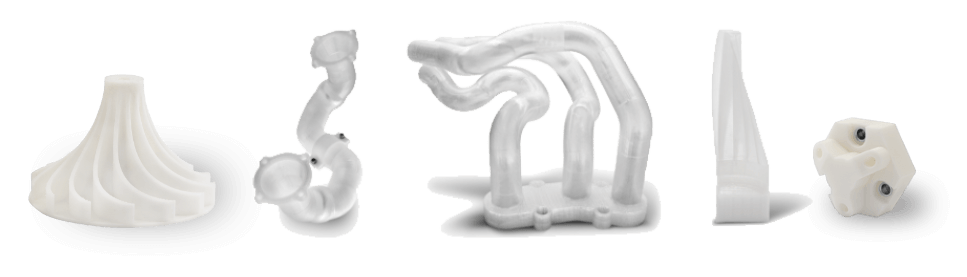

The precision of printouts for medical applications is guaranteed by VSHAPER 3D printers – specifically designed for one of the most demanding industry.

SOFTSHAPER – the professional software tailored to the needs of industrial printing machines in FDM technology, also compatible with low-budget 3D printers, has just presented the latest release of its essential functions. As the creators assure, it is worth to consider exchanging the existing software to a software well suited to high technological and material […]

3D VSHAPER Printers are gaining strength and popularity around the world. Thanks to cooperation with our Asian market distributor, Josh Chung from Tinjin Newtech, 3D Print enthusiasts will have the opportunity to talk about the production and possible use of 3D VSHAPER Printers on Taipei Int’l Mold & Die Industry Fair in Taiwan (TAIMOLD) from […]

The financial support of OP Smart Growth 2014-2020 has made the ongoing intensive work on the development of 3D VSHAPER possible. Worth 2,8 million euros ‘Globally innovative additive printer’ project, set up by the Polish producer, has been subsidized with 2 million euros.

Define business requirements and let us prepare an offer best suited to your needs.

Get a Quote