The improvement in the use of plastics in the industry, which we can observe, increases the requirements for the measurement correctness and quality management. Valued in industrial applications – PEEK – is an excellent example of the benefits of innovation in the field of polymers, on the other hand, it is also an excellent example to illustrate the technological requirements that one must meet to make production reasonable.

PEEK, a high-performance, temperature-resistant semi-crystalline polymer is often used as a replacement for metals in a wide range of industrial end uses.

It has proved particularly useful in the production of transplant components, due to the possibilities offered by 3D printing technology for forming complicated, non-standard parts. The mechanical and physical properties of the material itself (high chemical resistance/acids, bases) allow avoiding inconvenience in the body environment caused by metal parts. High temperature and abrasion resistance enable efficient work in severe operating conditions, also with lubricants, which contributes to broader use in the automotive industry. On the other hand, low gas emissions, even when exposed to relatively high temperatures, enable its use in vacuum technology, in which light materials are sought that can meet the restrictive requirements of research in the space environment.

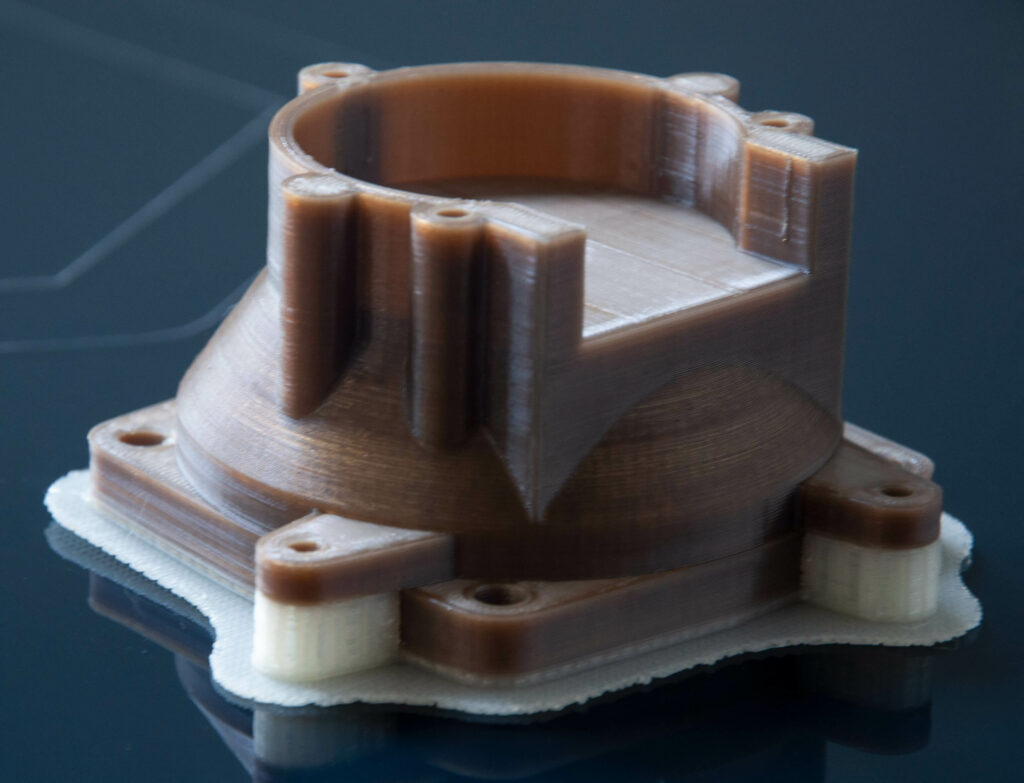

The conditions of thermal treatment during printing with PEEK can have a direct and indirect impact on its crystallinity and mechanical properties.High strength, wear and thermal properties mean that the process of forming melted PEEK requires particular parameters of printing machines. The main difficulty in forming PEEK parts during additive manufacturing is the high melting point of this material, which means that models can be subject to a significant temperature change during forming. These changes may result in high internal stresses, warping and delamination.

Therefore, it is essential during printing PEEK material to maintain optimal conditions such as the temperature of the nozzle and heat treatment possibility, i.e. equipping the printer with a closed heated chamber and heated work table. Such actions have a positive effect on increasing the ultimate strength of the formed parts.