Comparison of the 500 PRO and 500 MED 3D printers

3D printers are revolutionary devices that are changing our approach to production and creation in a variety of industries. This article will compare two models of the flagship VSHAPER 500 PRO and 500 MED printers. It will help you make an informed choice and find the 3D printer that best suits your needs.

Read more +

How are 3D scanners and 3D printers changing the way we design and manufacture?

In recent years, 3D scanners and 3D printers have changed the way we design and manufacture all kinds of objects. These innovative technologies not only provide new possibilities in creation, but also speed up and streamline entire manufacturing processes.

Read more +

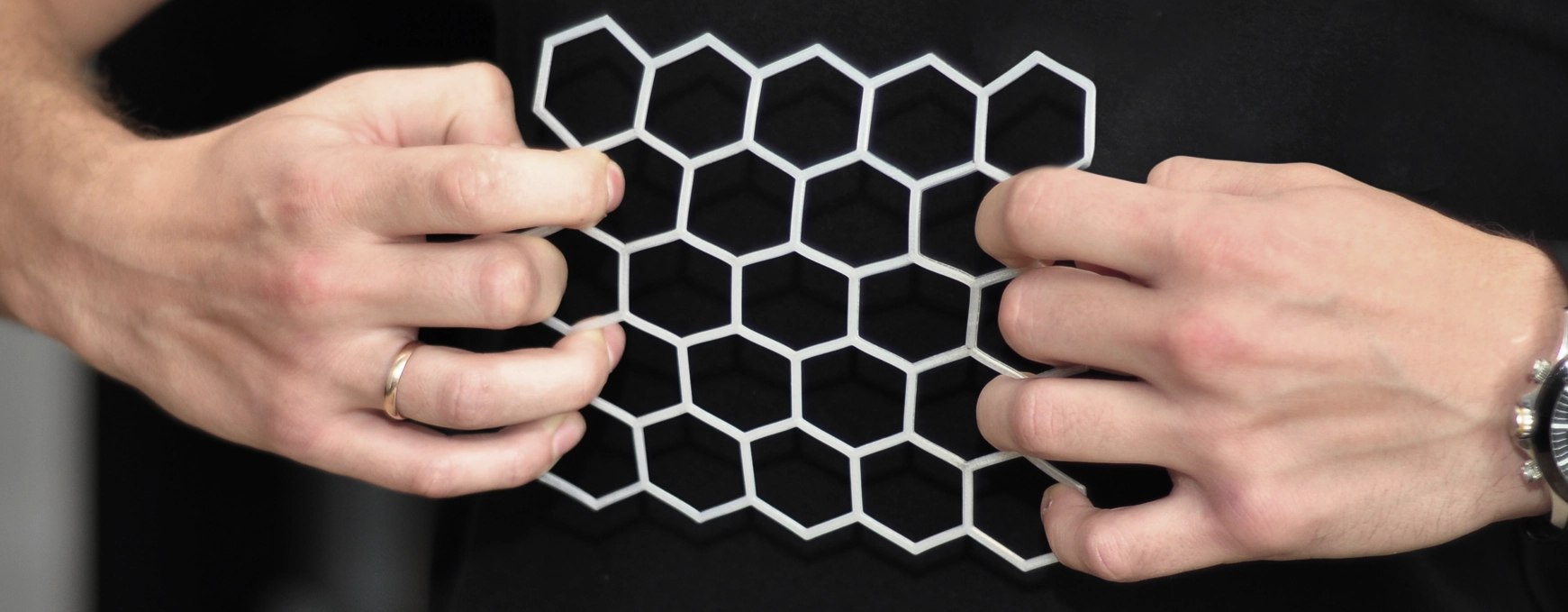

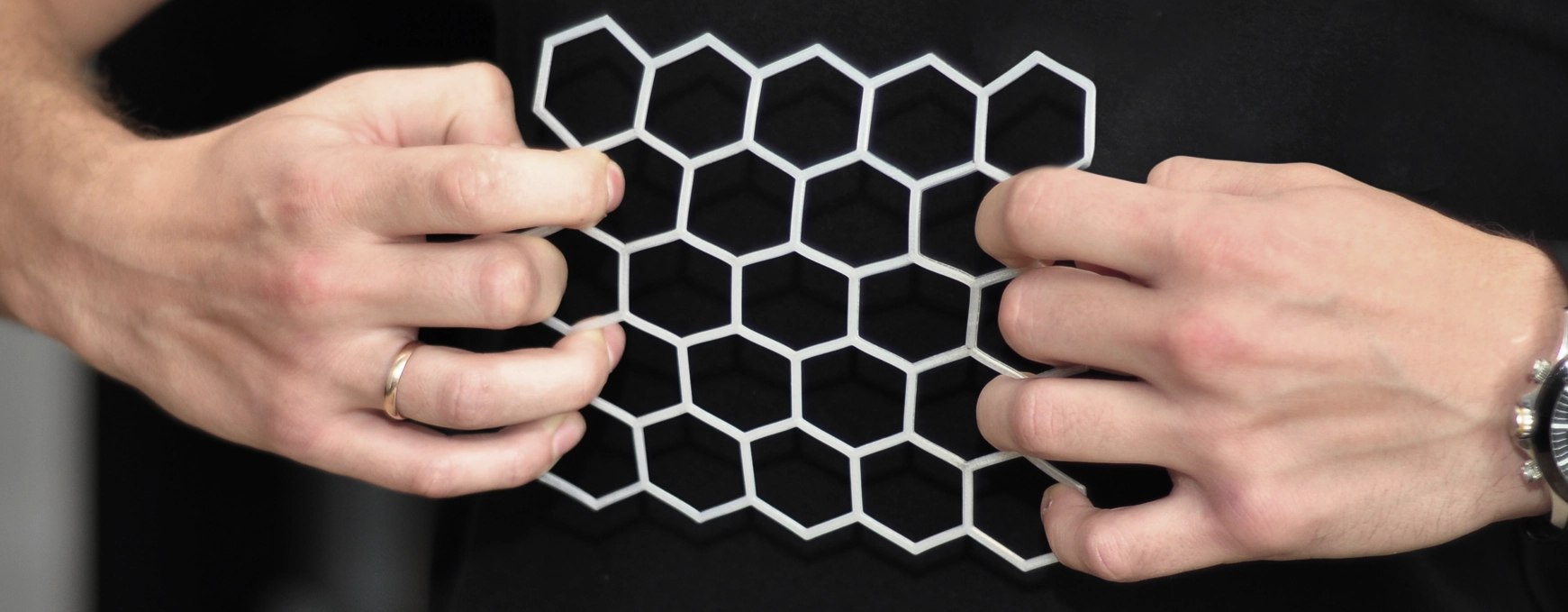

Strength of 3D printing

The strength of a 3D printed model is influenced by a number of factors, primarily the geometry/shape of the model, the printer on which the print is made and the temperature of the print, the type of material and the amount of outer contours and top/bottom layers and the degree of infill. Read the article […]

Read more +

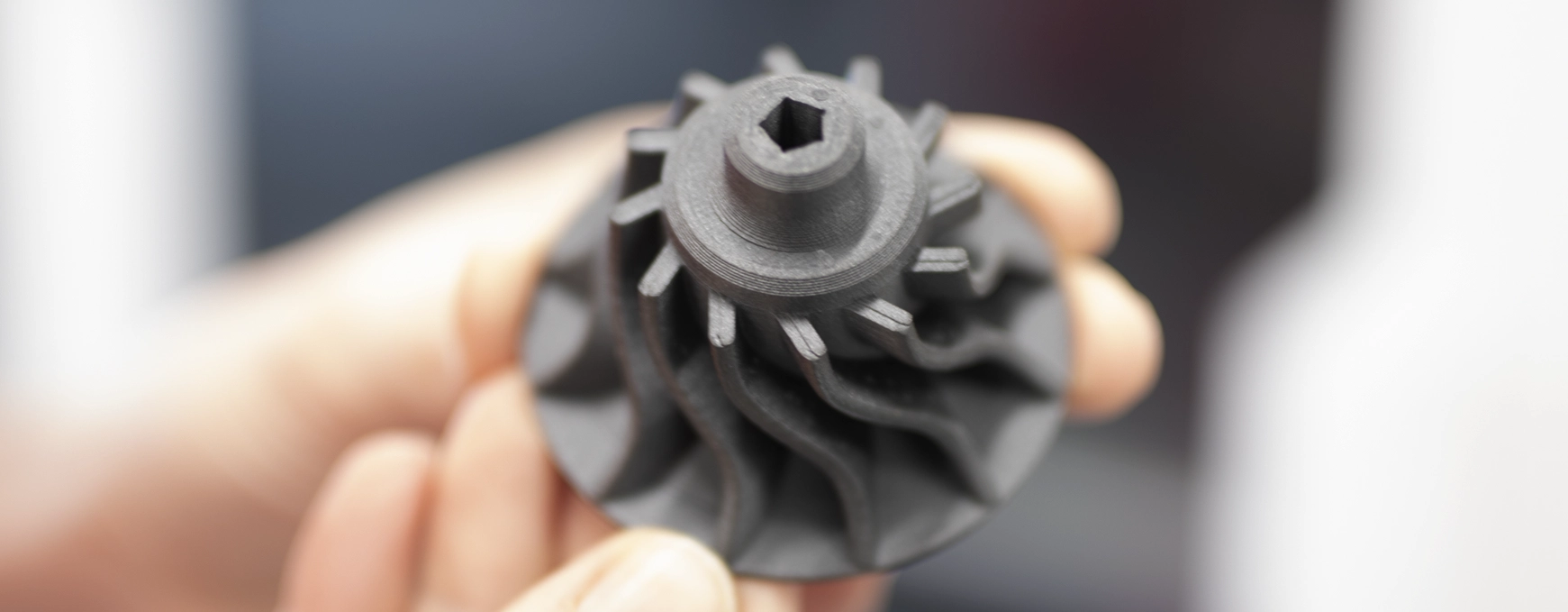

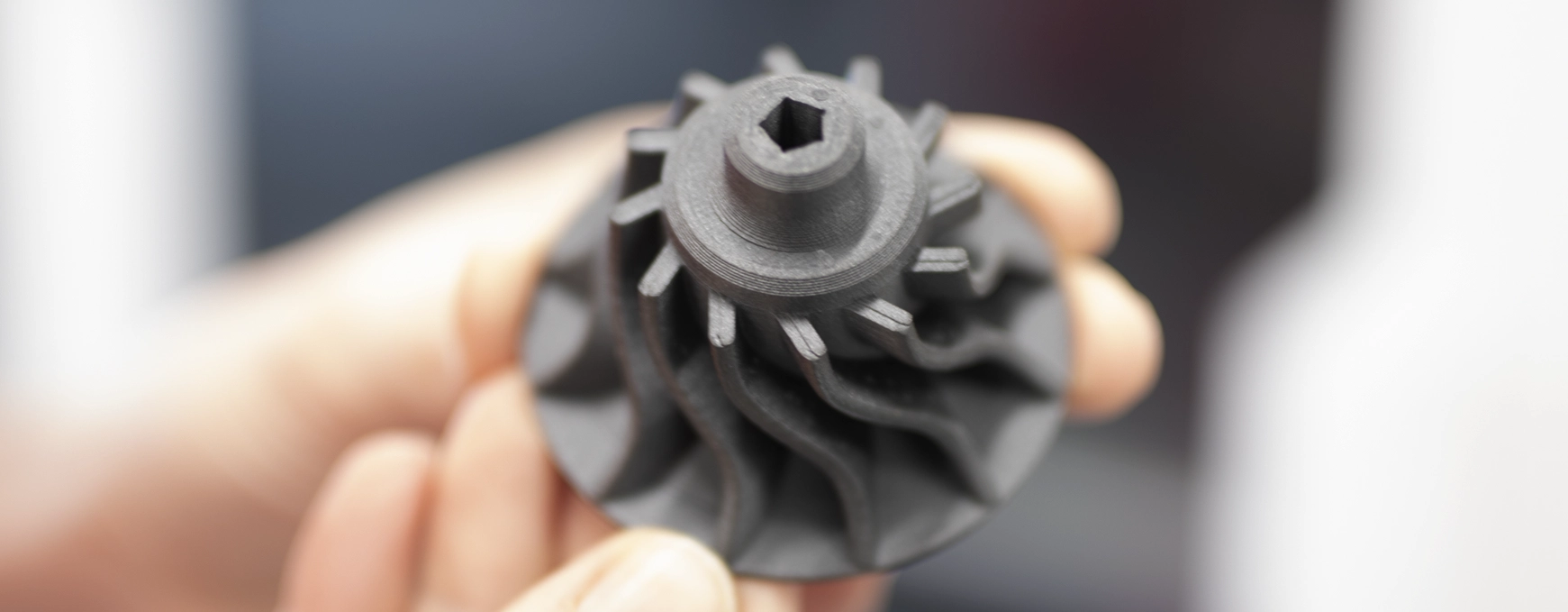

3D printing filament PA GF FILSHAPER

PA GF is a polyamide with glass fibre, a 3D printing filament used to print very durable components such as machine parts, tools or housings. This material requires care in setting the print parameters well and using the right printer.

Read more +

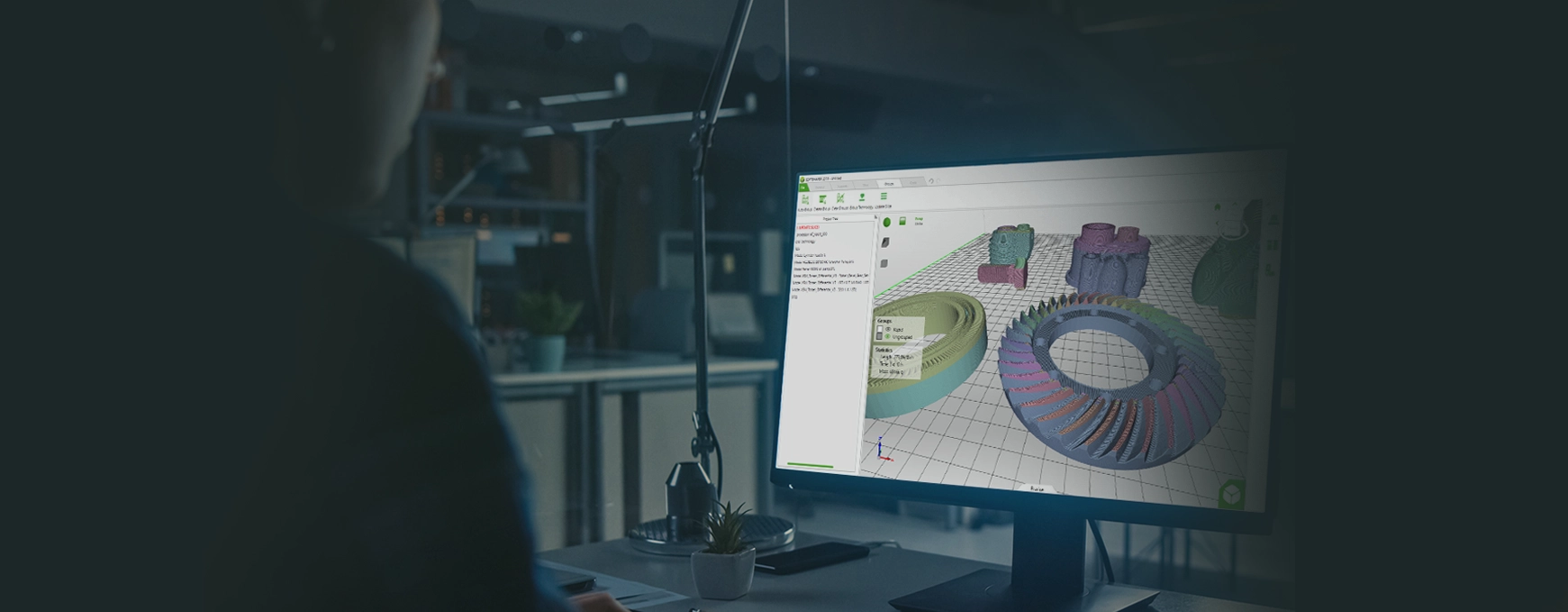

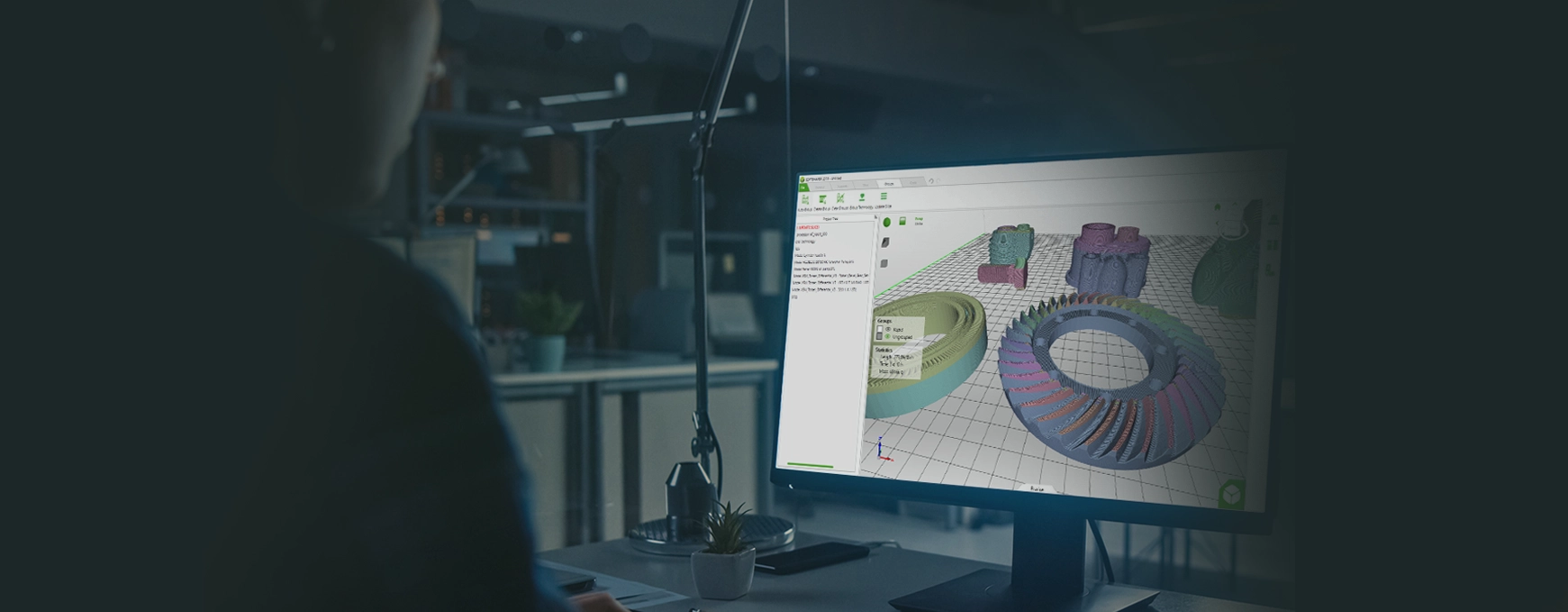

What features should 3D printer software have?

3D printer software is one of the most important elements responsible for the quality, efficiency and capabilities of prints.

Read more +

Strong 3D printing filament – PEEK GF

PEEK with glass fibre is material in the VSHAPER portfolio, a high-performance composite material with thermoplastic properties. It is a reinforced PEEK with 15 per cent glass fibre fill, harder than PEEK.

Read more +

Quality of small batch 3D printing production – tutorial

Watch the next episode of Softshaper Tutorials! Find out more about advantages of 3D printing small batch production line

Read more +

3D printer specifications. What to look for when selecting a 3D printer?

There are several elements to consider when choosing a 3D printer. Check out what 3D printer specifications you should pay attention to.

Read more +

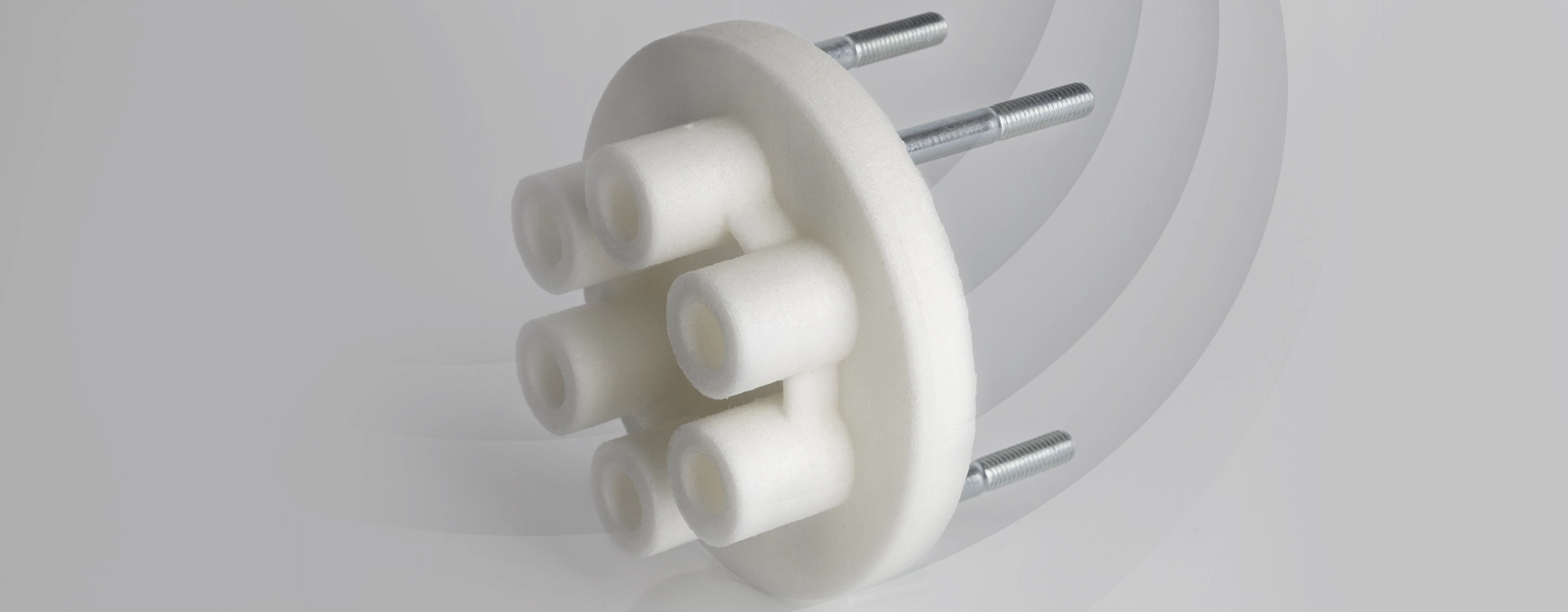

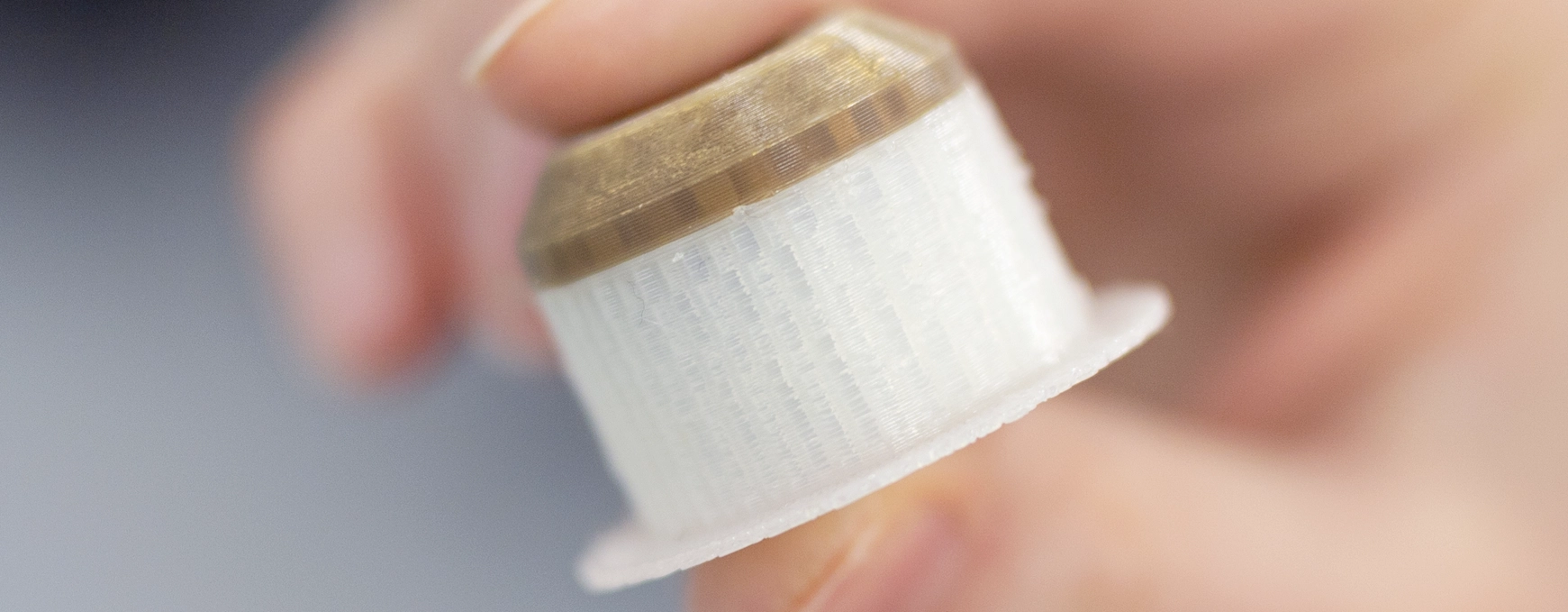

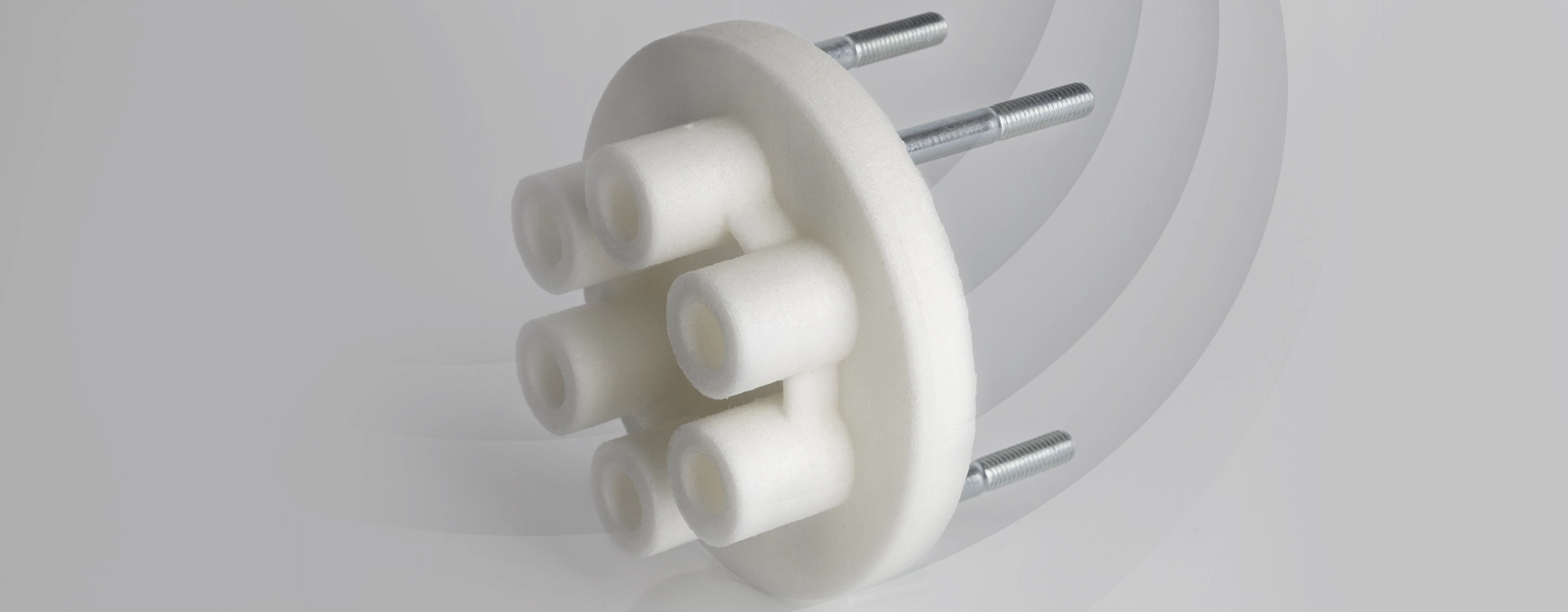

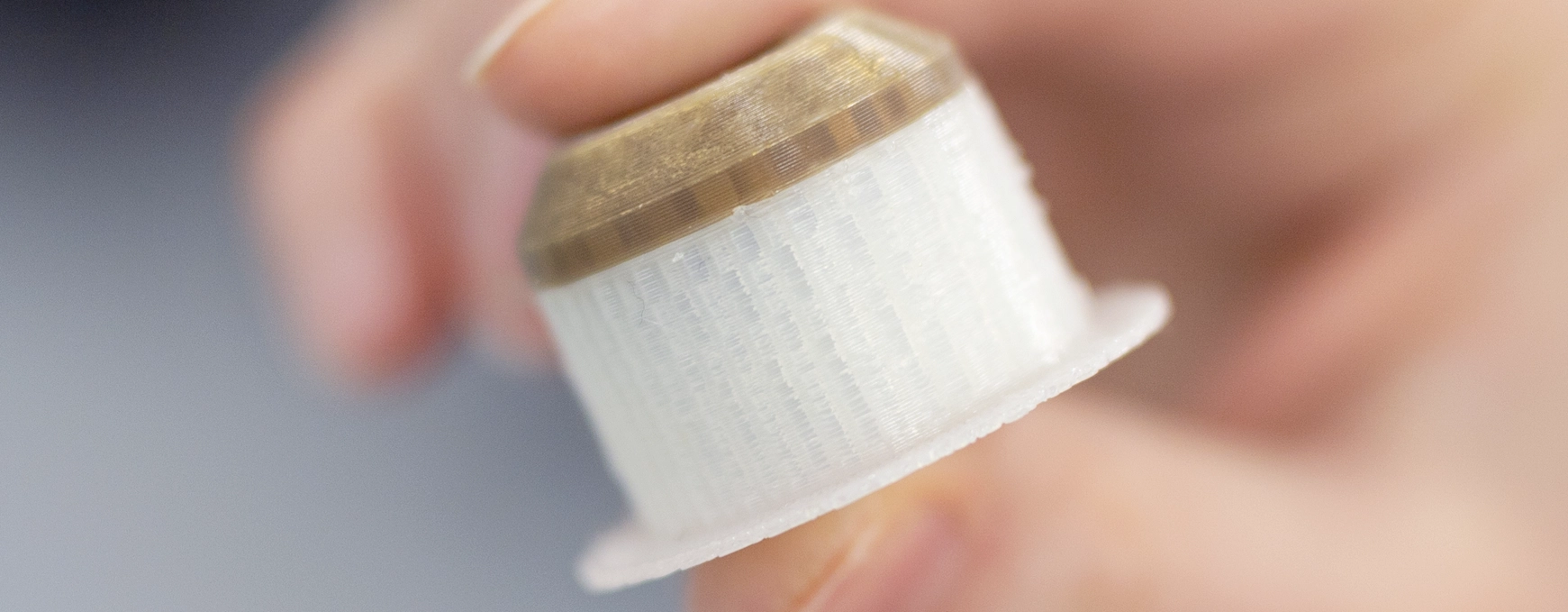

How to apply threaded inserts into 3D printed model? – tutorial

To find out how to apply threaded inserts using SOFTSHAPER, you have to watch our tutorial. See in our gallery prints with diffrent types of inserts inside of 3D printing models.

Read more +

3D printing, would it work for your industry? – part 1

3D printing is growing in popularity year on year. It is used in small businesses as well as multinational corporations.

Read more +

How to change infills in 3D printing models? – tutorial

How does layer grouping feature work ? The most important thing is using proper software to 3D printing. You can apply layer grouping feature and prevent wasting material during 3D printing. Also you manage the mechanical properties of the model. Find out more about 3D printing software – SOFTSHAPER. Learn more from first episode of […]

Read more +

PEEK CF filament for 3D printing – properties, applications

The best example of this is PEEK material with carbon fibre, which is an innovation of standard PEEK. How do they differ from each other? Explore the properties of PEEK CF FILSHAPER and find out in which industries PEEK CF will find application.

Read more +

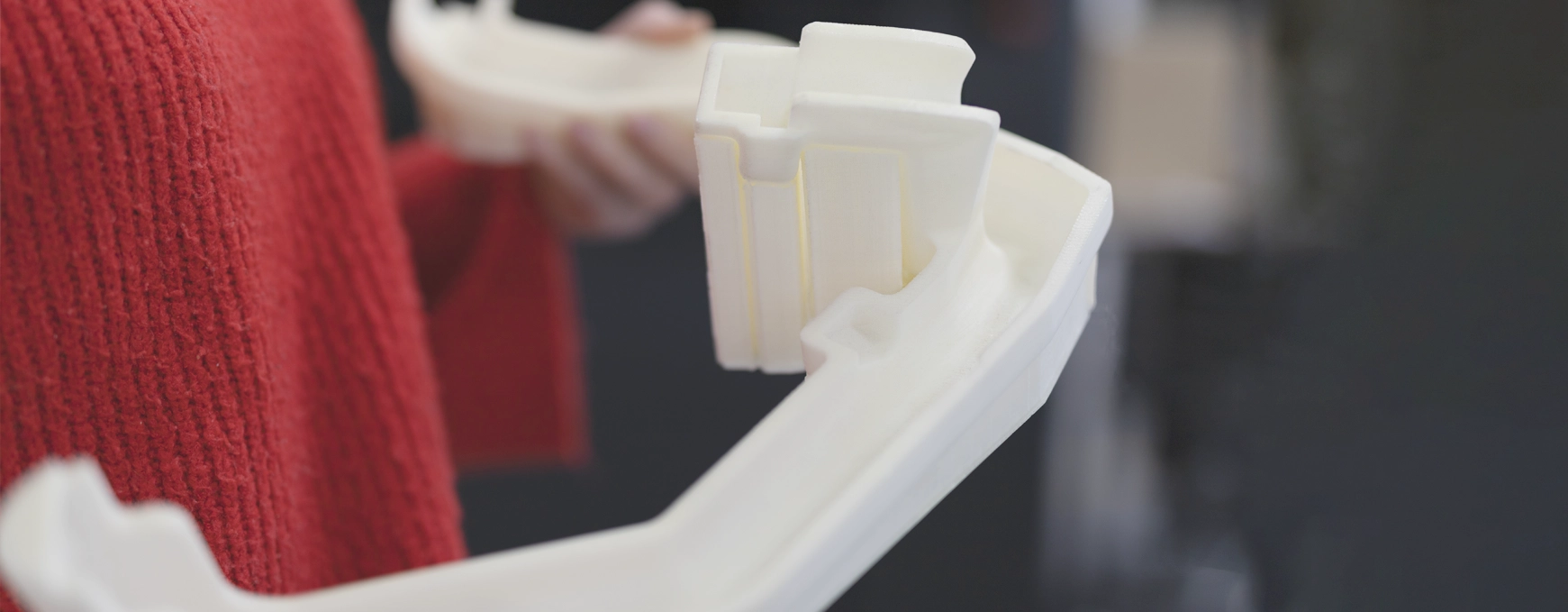

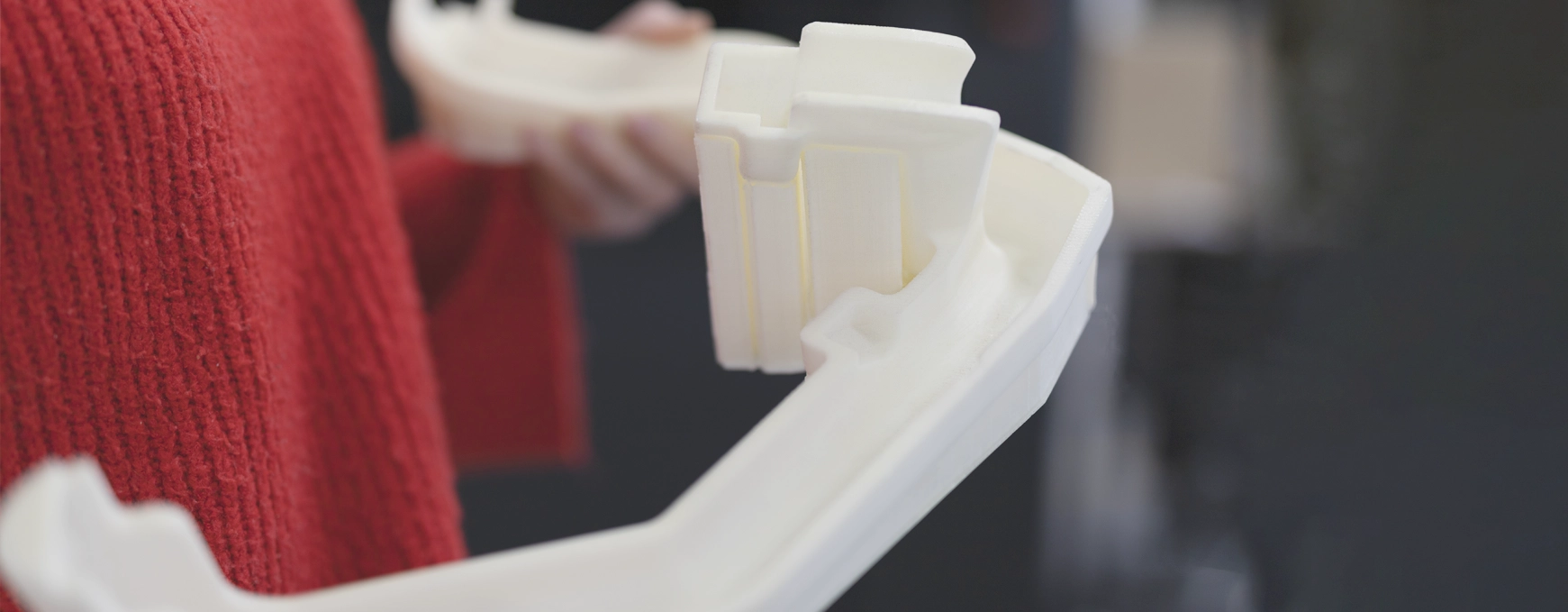

How to ensure dimensional accuracy of FDM 3D printed PEEK parts?

While FDM 3D printing, complications may occur when processing large-size elements, such as the two-piece 40 cm model shown in the photo above, which, in addition to restrictive dimensional parameters, required the clearance along the entire element to be maintained while maintaining high strength parameters.

Read more +

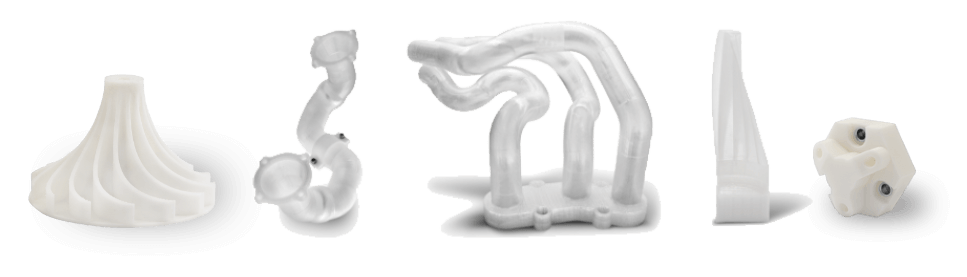

Soluble support material for PEEK – Why it matters.

Demographic changes and industry development generate increased demand and material consumption as well as the need to automate production. In this field, modern polymers – such as PEEK, support optimization, and in some cases replace the materials used so far.

Read more +

ABS (acrylonitrile butadiene styrene) – properties, uses and processing

ABS is a very popular material used for many everyday objects. ABS can be printed, extruded, injection molded and other processing methods. ABS can be used to make a wide variety of objects from toys to replica weapons to industrial machinery parts. In this article I will try to introduce the properties and applications of […]

Read more +

How does moisture affect 3D printing fiber?

All filaments for 3D printing FDM / FFF are hygroscopic, i.e., they absorb moisture from the environment in which they are located. Hygroscopicity is an undesirable effect in filaments for 3D printing. Plastic polymers consist of chains of molecules joined together. The absorbed water molecules destroy these chains, destroying the plastic and causing many problems […]

Read more +